With the continuous advancement of technology and acceleration of industrialization, the demand for electricity in factories is growing. How to use electricity efficiently, safely, and energy-savingly has become an important issue in factory operations. Smart power solutions for factories have emerged, which apply technologies such as the Internet of Things, wireless communication, and automatic control to achieve intelligent management and optimization of factory power usage.

The smart power solution for factories is a solution based on IoT technology, aiming to improve factory power safety and efficiency. Through smart hardware such as intelligent power distribution monitoring modules and remote control modules, it integrates and rectifies the factory's power system. Combined with a smart power management cloud platform, it performs fine-grained measurement, real-time monitoring, and intelligent control to achieve the goal of intelligent power management.

Main functions:

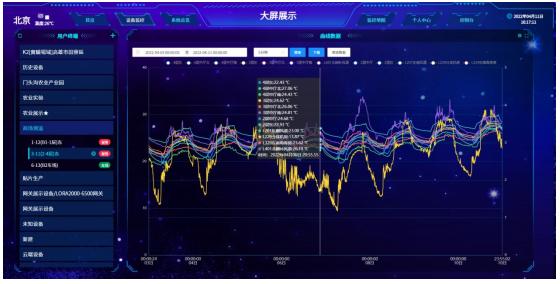

Real-time monitoring: By installing smart meters, smart sensors, collection devices, and other monitoring and collection equipment, the real-time monitoring of the electricity usage of various equipment in the factory is achieved, including voltage, current, active power, apparent power, power factor and other electrical parameters. These data are transmitted to the cloud platform wirelessly or via cable, allowing management personnel to view and analyze them at any time.

Intelligent Control: Integrated with intelligent power distribution monitoring modules and other systems, it can automatically adjust the operating status of equipment based on changes in equipment power parameters, perform operations such as timing switches, sensor intelligent linkage, manual switch linkage control, output interlocked electric control, time-based loop control, and time-based intermittent switches to achieve intelligent control of equipment, improving equipment operating efficiency and safety.

Equipment Protection: By storing and analyzing historical power usage data from the factory, abnormalities during equipment operation can be detected, such as overload, phase loss, short circuit, current limiting protection, and other abnormalities that may cause equipment damage or fire accidents. Immediately cut off the power supply and issue an alert for timely handling.

Data Management: Automatically store the factory's power usage data, generate visual reports, and store them on a cloud server for centralized processing and analysis. Management personnel can conveniently view and analyze the factory's power data, helping to understand equipment energy consumption and providing data support for decision-making.

Energy Saving Optimization: By analyzing historical power data, we can identify waste and irrationalities in power usage and propose targeted energy-saving measures and suggestions. For example, during peak electricity usage hours, automatically adjust the equipment operating mode and power to reduce the electricity load and minimize energy waste. At the same time, based on the factory's production plan and actual demand, arrange the supply and distribution of electricity in a reasonable manner to improve the efficiency of power usage.

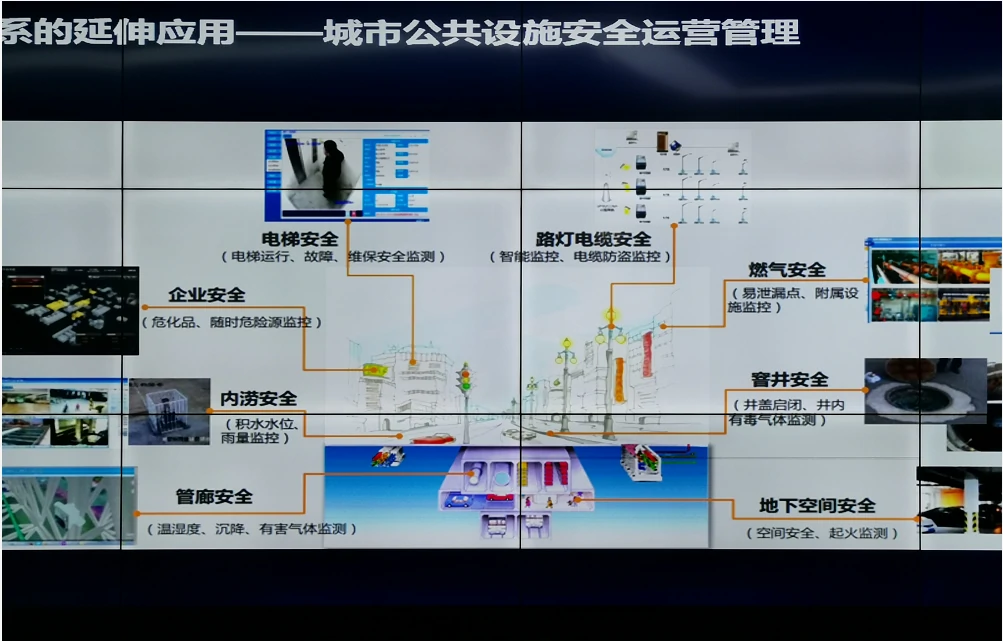

Other functions: Supports integration with industrial IoT solutions such as lighting systems, energy monitoring systems, and ventilation/HVAC control systems, with data sharing and control management on a single management cloud platform.

The smart power usage solution for factories can improve power safety and efficiency, reduce energy consumption and operating costs, and help enterprises achieve sustainable development.