We will present the performance, safe operation methods, and technical parameters of BKBPF three-phase unbalance automatic regulating device

The three-phase load imbalance automatic adjustment device is mainly used on the user side of low-voltage power distribution to control the three-phase current imbalance, low phase voltage and compensate for reactive power, and optimize power quality. It can compensate for three-phase unbalanced current and reactive power at the same time to achieve continuous and dynamic compensation.

It can comprehensively improve the power quality of the station, as follows:

● Solve the problem of three-phase imbalance in the distribution network and reduce line loss;

●Stabilize the three-phase voltage, improve the quality of power supply, and improve the power environment;

● Solve the problem of single-phase overload of transformers and improve the operating life of transformers;

● Reactive power balance to improve the effective output capacity of the distribution network;

Unpacking and lifting

Lifting precautions:

Safety assurance measures to prevent crane tipping measures:

The road at the hoisting site must be leveled and solid, and the backfill soil and soft soil layer should be treated. If the soil is soft, the road should be paved separately. The crane shall not be parked on the slope to work, and the two sides of the crane shall not be allowed to be high and low.

It is strictly forbidden to overload hoisting.

Diagonal cranes are prohibited. Diagonal cranes can cause overload and wire rope outflows, and even cause rope breakage and rollover accidents. Diagonal cranes can also cause heavy objects to swing quickly after leaving the ground, which may injure people or other objects.

The sling of the binding member must be calculated, all lifting tools should be regularly inspected, the damaged person should be identified, and the binding method should be correct and firm to prevent the sling from breaking or slipping off the component during hoisting, causing the crane to lose weight and tip over.

The mass that the crane can support must be within (mass).

It is forbidden to carry out lifting operations in the case of level 6 winds.

Commanders should use unified command signals, which should be clear and accurate. Crane operators should obey commands.

Measures to prevent falls from high altitudes:

Operators must use safety belts correctly when working at height. Safety belts should generally be hung high and used low, that is, the hook and loop of the safety belt rope end should be hung at a high place, while the person should operate at a low place.

When using a skid, people should stand steadily, such as scaffolding nearby or components have been installed, they should hold it with one hand and operate it with the other. If the prying distance is large, it should be gradually pryed, and it is not advisable to rush for success.

When workers need to work at height, they should set up temporary operating platforms as much as possible. The operating table is a tool type, with a width of 0.8~1.0m and is temporarily fixed on the upper part of the column with angle steel cleats, 1.0m~1.2m lower than the installation position, and workers can correct and weld the roof truss on it.

When walking on the chords of a suspended roof truss, safety railings should be installed on it.

The ladder for climbing must be firm. When used, it must be tied with a rope to the fixed member. The angle between the ladder and the ground is generally 65~70 degrees.

When the operator passes on the scaffolding, he should concentrate his thoughts to prevent stepping on the headboard.

When installing floor slabs or roof panels with reserved holes, they should be covered with wooden boards in time.

Note: Operators are not allowed to wear hard-soled leather shoes to work at height.

Installation method:

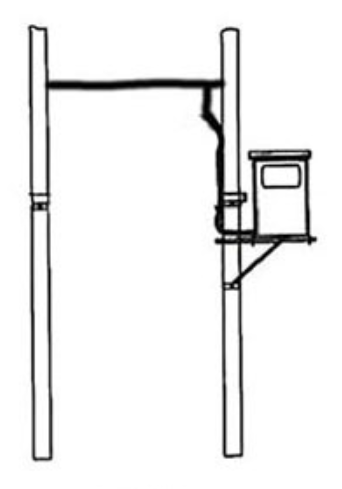

Outdoor suspension installation methods are divided into double column installation and single column installation, as shown in (Figure 1).

|  |

| Twin post mounting | Single post mounting |

Twin post mounting

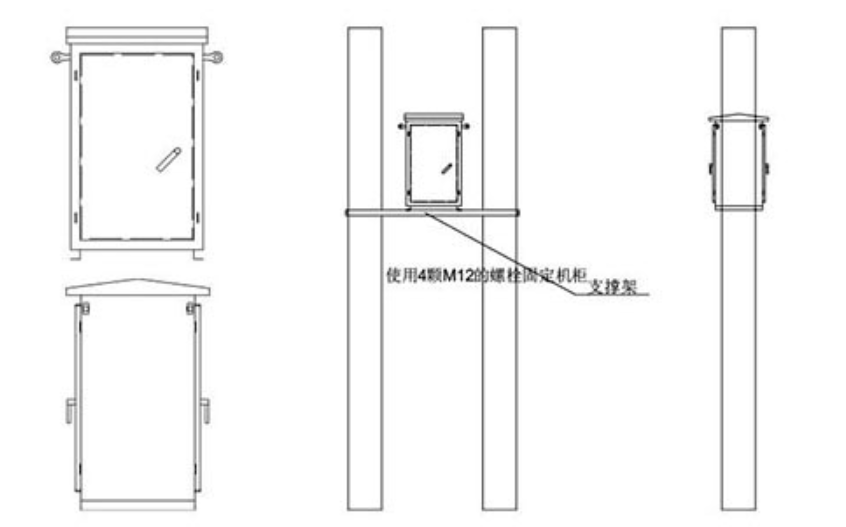

The equipment is installed outdoors between two wire poles, as shown in (Figure 2).

The equipment is generally installed between outdoor utility poles, in order to ensure the convenience and safety of installation, the spacing between the upper wire and the bottom of the equipment is installed between the channel to ensure a distance of 1200mm, and the installation is first used with a special one

Install the two channel bars on the outside of the two poles with hoops, and then use 4 M12 screws to install the bottom of the equipment on the channel

Single post mounting

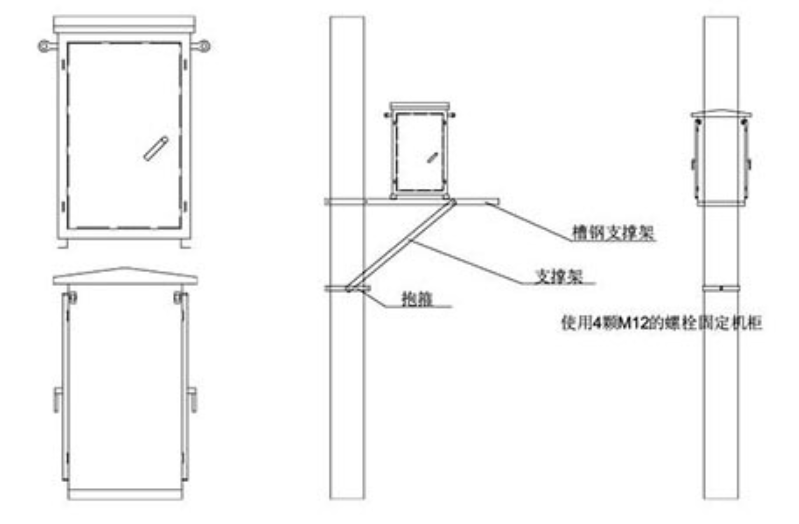

The equipment is mounted on a single telephone pole, as shown in (Figure 3).

First, the two channel bars are fixed to the poles, and then the two support poles are used to install them diagonally on the lower part of the two trough marriage steels, and the other ends of the two support poles are connected to the lower part of the pole to play a supporting role.

The bottom of the equipment is fixed to the outside of the two channels using four M12 bolts.

Note: For easy maintenance, the minimum distance of the equipment from the pole is 200mm, considering the load-bearing safety, no more than 300mm

Note: For both installation methods, the height of PV8 after installation should be higher than the height that can be touched by people